Estimated reading time: 3 minutes

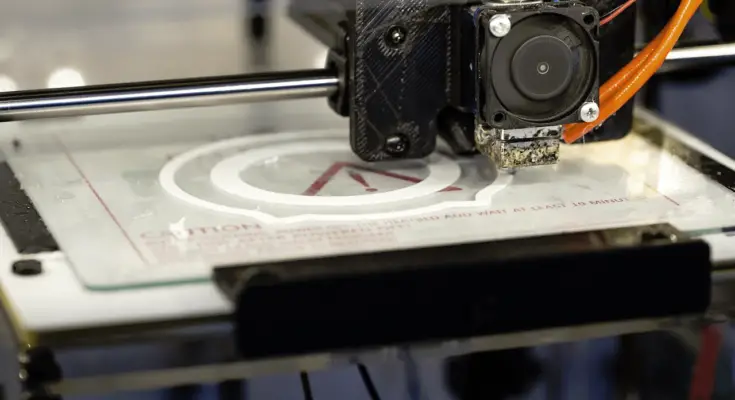

Newcomers to the world of 3D printing have lots to discover and tons of potential benefits to harness thanks to this amazing technology.

Of course as with any process, there is a learning curve to overcome and some potential pitfalls that you will want to avoid.

Here is a look at the main errors that first-timers can make when leveraging 3D printing without prior experience to fall back on.

Choosing hardware unsuitable for non-technical users

There are lots of different products on the market that can allow you to carry out 3D printing in your own home, or as part of your business. However, whether you are taking advantage of the 3D printing in Austin or getting your fix in Nashville or anywhere else nationally, you should aim to invest in equipment that is fit for beginners who lack in-depth technical knowledge.

While more expensive and complex kit may catch your eye, you will doubtlessly find yourself struggling to make the most of it if it has too many bells and whistles. Instead opt for 3D printers for beginners and use this as the foundation on which you can build in the future.

Overlooking material properties

3D printers can produce parts and components using a number of different materials, but you cannot simply knock up a design and assume that it will be achievable using whatever material you happen to have lying around.

There are complex and varied properties to each material available to you. For example, PLA is inexpensive and straightforward to use, but is also brittle, melts easily and is not especially strong, while PETG is more flexible and sturdy, but can adhere to the print bed if it is not heated.

Check the compatibility of your printing equipment before buying materials, as well as adapting your design to work with the benefits and limitations that it offers.

Using low resolution files

In a 3D printing context, the resolution typically refers to the complexity of the mesh that will be created, usually with triangles being the smallest constituent shapes within it.

If the file you create in the best modelling software to send to your printer is of a low resolution then the end product will appear ‘pixelated’, much like a low-res image file displayed on a computer.

That is not to say that you should just opt for the highest resolution available either, as doing this will make the file unwieldy and could mean that the printer will not even accept it. Set suitable tolerance levels and resolutions to the project in hand and experiment with different options to see what works best for you.

Ignoring preliminary setup steps

Once a 3D printer arrives you may be desperate to start using it straight away, but this eagerness can lead to errors in the initial setup, which in turn translates into suboptimal performance or even outright equipment damage.

Always read the instructions and follow the necessary steps to prepare the machine for use, not just the first time you fire it up but every time you go to print, and you should be fine!

Share this content: